Upgrade Your Manufacturing with NSO4000 Series

At Netsight One, we’re proud to introduce NSO4000 – our advanced AI platform, a robust industrial aggregator that is revolutionizing manufacturing and consistently exceeding industry benchmarks.

Designed for the challenges of modern manufacturing, the NSO4000 series offers a comprehensive suite of tools to optimize efficiency, ensure quality, and drive sustainability across industries.

Whether you’re in automotive, medical, toys, textile, general consumer electronics manufacturing or any other fast-paced sector, the NSO4000 series provides the smart, AI-powered solutions you need to stay ahead.

Unlock the Full Potential of Smart Manufacturing with NSO4000

The NSO4000 is designed to handle the demands of modern manufacturing with robust specifications. From its wide temperature range and vibration resistance to its high-speed communication options, NSO4000 has already proven to be a reliable component in all critical phases of optimizing modern, AI-driven industrial environments.

With the distribution of the NSO4000 platform and its variants, NETSIGHT ONE has already made a significant impact in major critical manufacturing sectors, driving transition to smart factories.

Our journey would not have been possible without the trust of our customers and the commitment of our team. Together, we’ve unlocked new possibilities:

- Real-time insights into production and inventory.

- Safer working environments with advanced safety monitoring.

- Reduced environmental impact with smart resource utilization.

Why NSO4000

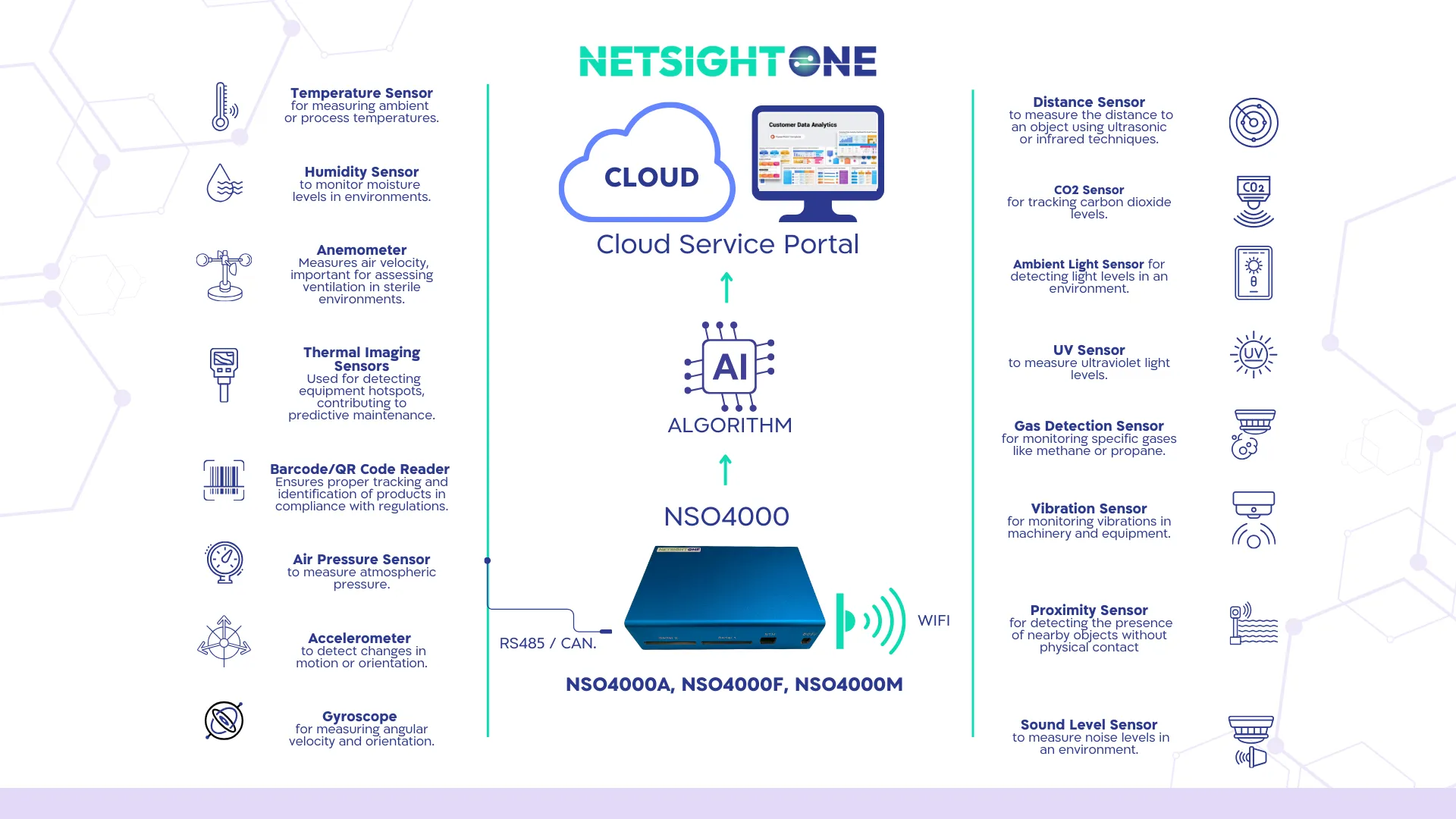

platform that harnesses leading-edge AI capabilities and advanced sensors to connect and integrate across your factory floor, collecting real-time data on key parameters such as:

- Temperature & Humidity: Monitor environmental conditions to ensure optimal product quality and prevent spoilage.

- Vibration: Detects early signs of equipment wear and tear, enabling proactive maintenance.

- Pressure: Monitor pressure levels in various processes, ensuring consistent and efficient operations.

- Energy Consumption: Track energy usage across different areas of your facility to identify areas for optimization.

- More Advanced Sensors

Key Features of NSO4000

Real-time Data Acquisition & Analysis:

- Collect high-resolution data from a diverse range of sensors.

- Utilize advanced analytics and AI algorithms to identify trends, anomalies, and potential issues.

- Generate real-time dashboards and reports for immediate insights.

Edge Computing for Enhanced Performance:

- Process data locally at the edge of the network for faster response times and reduced latency.

- Improve operational efficiency and minimize reliance on cloud connectivity.

Predictive Maintenance:

- Anticipate equipment failures before they occur, minimizing downtime and costly repairs.

- Optimize maintenance schedules and reduce unplanned downtime.

Quality Control Enhancement:

- Monitor production processes in real-time to ensure consistent product quality and identify defects early on.

- Reduce scrap rates and improve customer satisfaction.

Enhanced Safety:

- Monitor environmental conditions and identify potential safety hazards.

- Ensure compliance with safety regulations and improve workplace safety.

Scalability and Flexibility:

- Easily adapt to your evolving needs and integrate with existing factory systems.

- Scale the platform as your business grows.

Robust Cybersecurity:

- Protect your data with advanced security measures, including encryption and access controls.

Technical Specifications at a Glance

| Feature | Specification |

| Sensor Inputs | 16 channels, up to 16Mbps data rate. |

| Communication | WiFi, CAN bus, RS485, Ethernet |

| Power Consumption | 15W typical, 25W max |

| Input Voltage: | 5V – 12V DC ±10% |

| Operating Temperature | -40°C to +85°C |

| Storage Options | Local (32GB) and Cloud (Unlimited) |

Unleash New Manufacturing Potential with NSO4000: Get in touch for a demo!

NSO4000 Variants for Specific Industry Needs

Designed for the challenges of manufacturing in the smart, fast-paced era, the NSO4000 variants deliver a targeted suite of tools to optimize efficiency, ensure quality, and drive sustainability across specific industries.

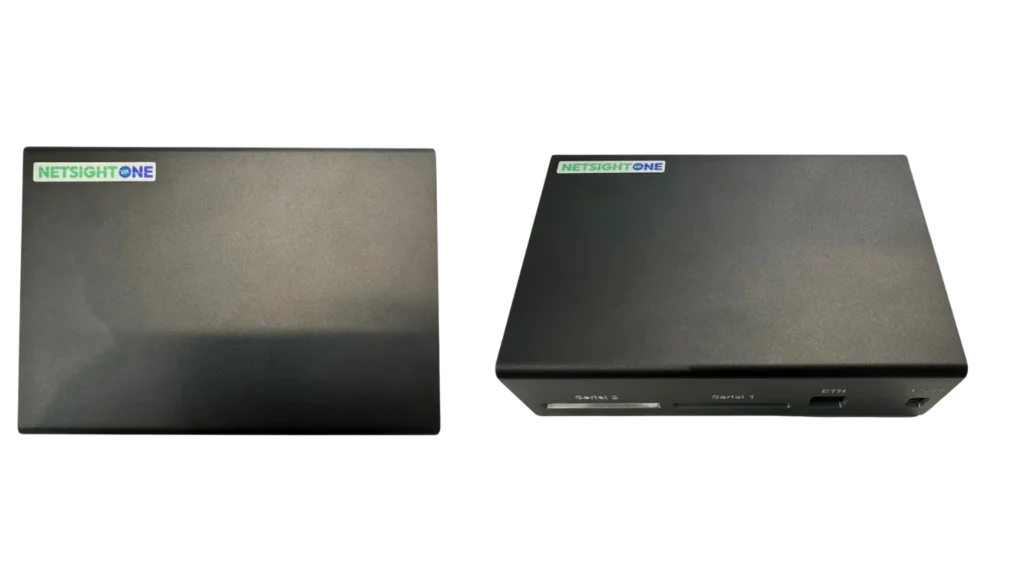

NSO4000 (Core Model)

- Purpose: High-speed production environments.

- Key Specs:

- High-frequency sensor support.

- Advanced real-time data processing.

- Best For: Automotive, electronics, and fast-moving assembly lines.

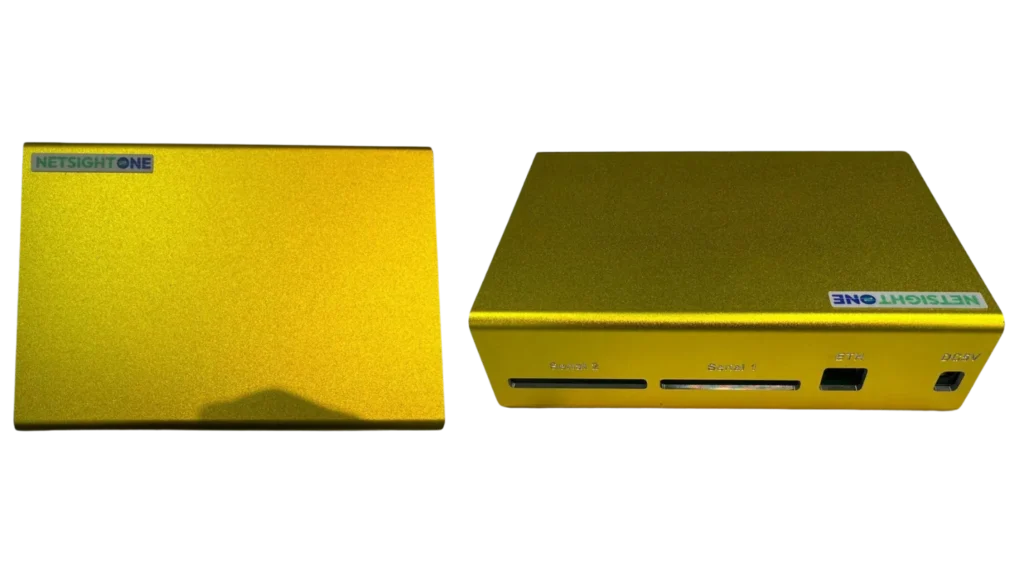

NSO4000F (Fast Model)

- Purpose: High-speed production environments.

- Key Specs:

- High-frequency sensor support.

- Advanced real-time data processing.

- Best For: Automotive, electronics, and fast-moving assembly lines.

NSO4000M (Medical Model)

- Purpose: Precision monitoring in medical manufacturing.

- Key Specs:

- Compliant with ISO 13485.

- Environmental sensors for cleanrooms.

- Best For: Pharmaceuticals, medical devices, and biotech.

AI-Powered Insights and Cloud Connectivity

NSO4000 leverages advanced AI algorithms to provide:

Integration & Reporting:

Enable robust system integration with APIs for data access, support various export formats, automate report generation, and create customizable dashboards for insightful analytics.

Anomaly Detection:

Identify and alert deviations during production in real-time, enabling proactive intervention to address issues before they escalate, thus maintaining operational integrity.

Process Optimization:

Leverage data analytics to pinpoint inefficiencies and bottlenecks, allowing for informed adjustments that enhance overall workflow efficiency and productivity in manufacturing.

Smart Pattern Recognition:

Utilize advanced analysis to classify machine operations, detect anomalies, optimize production cycles, and monitor quality to minimize defects and enhance sustainability metrics.

Machine Learning Features:

Employ adaptive algorithms to learn from historical data, recognize patterns, anticipate maintenance needs, and optimize performance for continuous improvement in manufacturing processes.

Integration & Reporting:

Enable robust system integration with APIs for data access, support various export formats, automate report generation, and create customizable dashboards for insightful analytics.

With its cloud-based architecture, NSO400 enables:

- Remote Monitoring and Control: Access and manage your operations from anywhere.

- Scalability and Flexibility: Easily adapt to changing needs and scale your operations.

- Data Centralization: Consolidate data from multiple sources for a comprehensive view of your operations.

Transforming Industries Worldwide

Our vision has always been to revolutionize manufacturing through smart, AI-powered solutions, and we are proud to have partnered with numerous industry leaders, in implementing NSO4000 across their operations.

The NSO4000 series has already made a significant impact in diverse sectors:

- 30% reduction in equipment downtime through predictive analytics.

- 20% savings in energy consumption via real-time optimization.

- Enhanced compliance with standards like ISO/TS 16949, ISO 13485, ISO9000 and ISO14001

Why Choose Netsight One?

Expertise You Can Trust:

As a main distributor, we bring deep knowledge of the NSO4000 series and its applications.

Comprehensive Support:

From consultation to installation and beyond, we’re with you every step of the way.

Tailored Solutions:

We help you select the right NSO4000 variant for your unique operational needs.

Customer Success Stories:

Our clients in critical industries have achieved remarkable results with the NSO4000 series.